WMS is the abbreviation for Warehouse Management System.

A WMS, a Warehouse Management System, is a software application used to manage warehouse, storage, and distribution center operations.

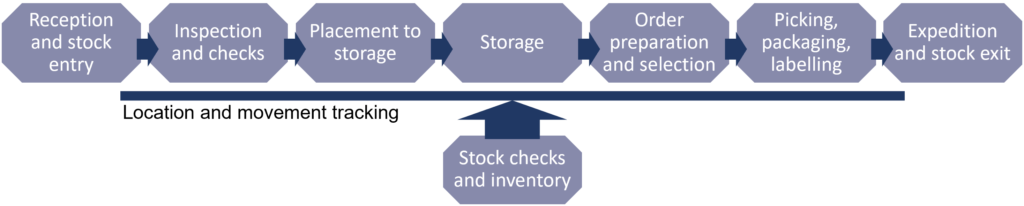

The basic functions of such a system cover activities such as the reception of goods, storage, inventory control, picking, order preparation, and expedition.

A key function of this software is the capture of the incoming materials at reception and the identification of any discrepancies between the physically delivered goods and the planned ones.

The system also monitors the exact location of goods (for example the rack and shelf number) inside a warehouse.

These functionalities and constant updates allow a WMS to provide an actual stock inventory in real time enabling the identification of re-supply, stock replenishment or production needs when compared to the incoming orders and forecasts.

On an operational level, a WMS is a key tool for order preparation as it enables the location of goods and assists with the picking, packaging, documentation, and labeling.