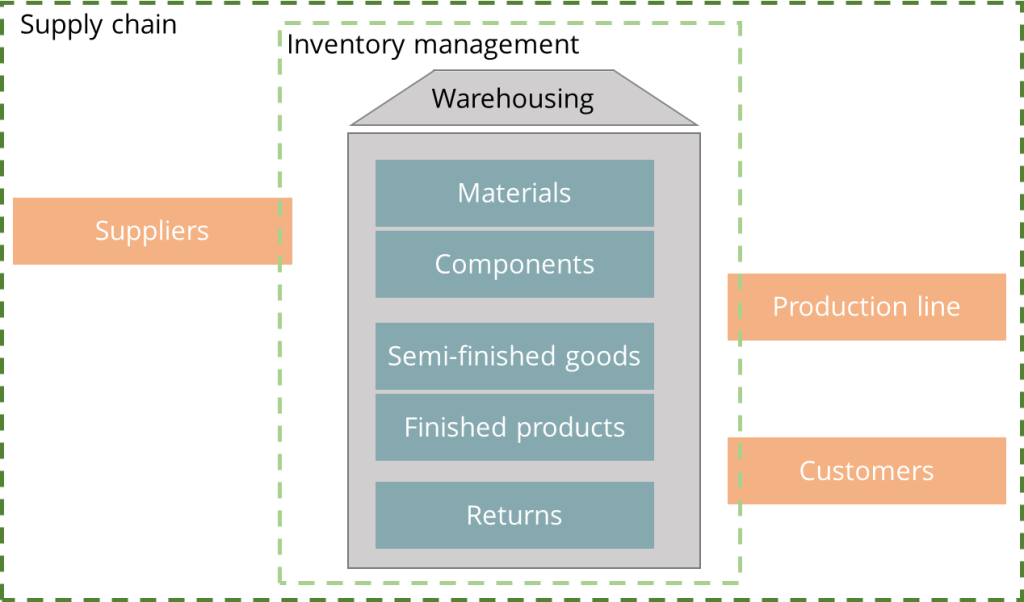

Inventory management can be seen as a function which aims at ensuring the smooth sourcing, production and delivery of products by ensuring that all required materials, components, and finished products are available on time and in sufficient quantity.

The term inventory refers notably to all materials and items stored in a warehouse and therefore the warehouse management team is a key player in a company’s inventory management efforts.

The Inventory management function, which is a key part of the supply chain, works to ensure that all needed materials and components are ordered and received from suppliers in sufficient quantities and in a timely manner in order to be able to support the production line.

It will also manage the inventory levels of semi-finished products to further support the production line as well as the finished ones and strive to ensure they are available in sufficient quantities to answer to the customer demands.

Finally, it will also monitor and manage the goods returning from customers or from the production line.

Inventory management also generally aims at keeping the levels of stock (inventory) and their related costs as reasonable as possible without endangering the supply or production chain.